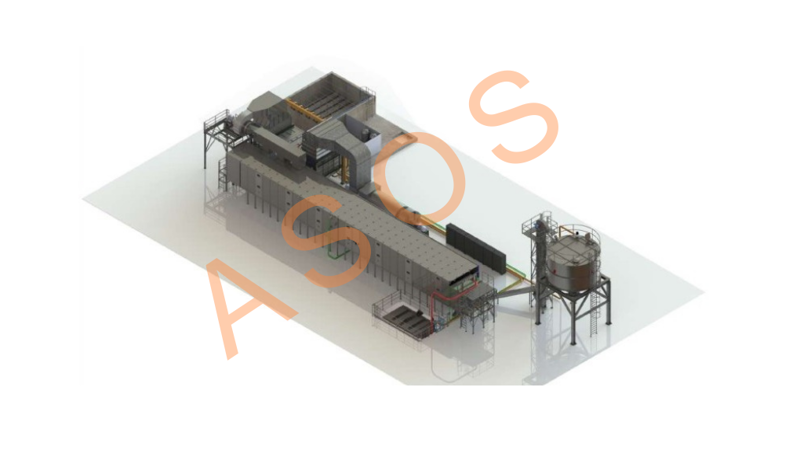

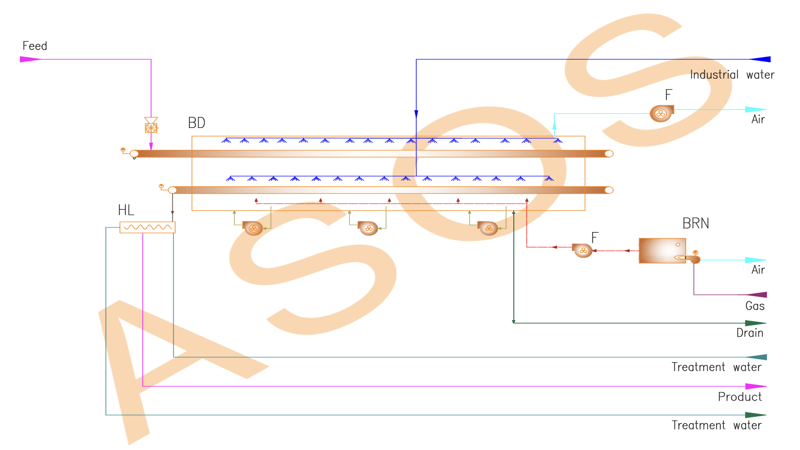

Belt Dryers ensures that the moist product is transported horizontally by means of steel pallets bedded on chains and dried with the hot air. Belt Dryers are generally used for wastewater treatment sludge, manure, sawdust, bark, etc. In the environment and waste industry. It is preferred for drying products.

With Belt Dryers, 20-25% dry matter ratios in wastewater treatment sludge can be reduced up to 90% dry matter ratios. The reasons for drying the sludge include reducing the amount of water in the sludge and thus reducing the amount of sludge, increasing the calorific value of the sludge and thus facilitating the combustion of the sludge, cleaning the sludge, stabilizing the sludge, obtaining a fertilizer and sludge with a high market value.

Advantages:

- It is suitable for drying granular products of 20 mm and above or products

- Maximum efficiency with long drying time for products with high humidity and difficult to dry

- Possibility of different drying times with adjustable belt system

- Belt system made of special steel

- High flow circulation fans

- Insulated cabins

- Compact and robust stainless steel design

- Low maintenance and long lifespan