Paddle Dryers are indirect type dryers that are widely used for drying or cooling sludge or crystalline & granular materials through mild heat transfer. They are versatile dryers that can be used for materials of various types and properties.

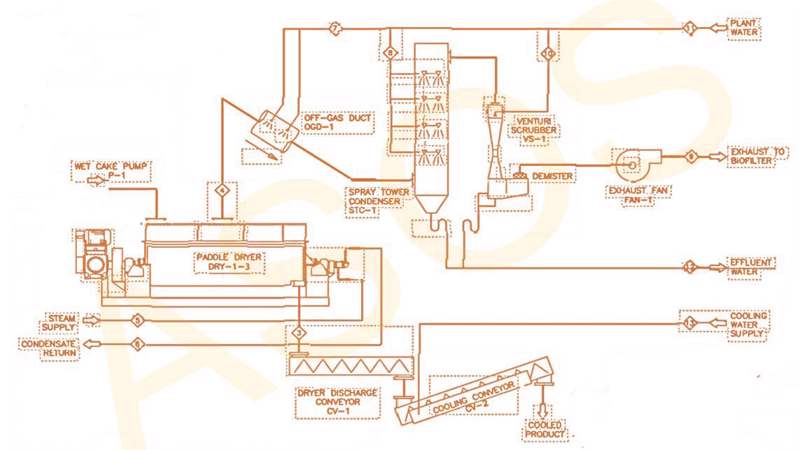

The paddle dryer consists of a double-shaft horizontal body mounted with hollow blades. Pallets are specially designed to enable them to clean themselves. Steam or hot oil is passed through the dryer body and wings to heat all internal surfaces.

The moist product is fed into the dryer from one end and moves towards the other end, where it is dried by contacting the hot surface of the pallets and the container. The dry product is discharged from the bottom of the paddle dryer. For heat-sensitive products or products with high organic content, the pallet dryer can be operated under vacuum.

Advantages:

- Low operating cost high efficiency

- Suitable for Mud and Crystal materials

- Initial particle size is maintained

- Requires less space with its compact structure

- Easy selection of energy source such as steam, hot water, hot oil

- Environmentally friendly with minimum amount of exhaust air

- Low maintenance costs