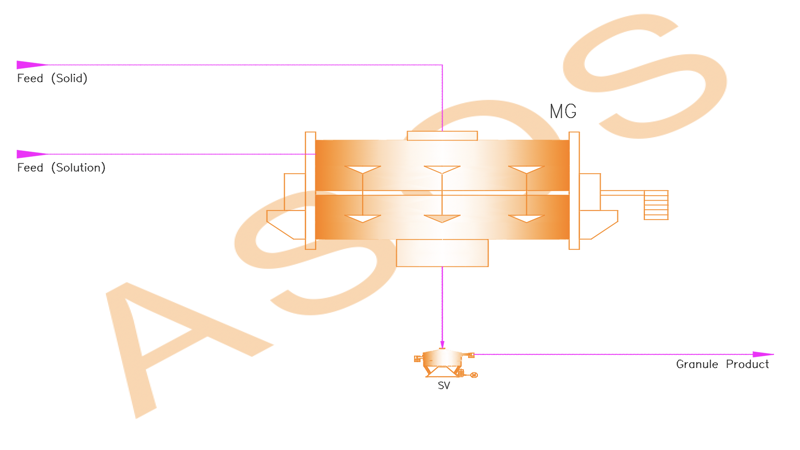

Mixer type granulators provide granulation and agglomeration processes with mechanical mixing method. There are various types of mixer granulator designs developed for different products. Considering the characteristics of the raw material and the desired final product, the design of the mixed granulator is decided.

The fluid selected as the binder for granulation is sprayed through the spray nozzle placed on the area in the mixing zone and provides agglomeration. By controlling the amount of liquid-solid phase and the speed and time of mixing, the desired size and density of the final granule product is obtained.

Mixer type granulators can greatly reduce the amount of binder used and thus allowing optimization of the drying time compared to traditional granulation technologies. In this granulation process, the character of the granule product is homogeneous and suitable for working with high efficiency.

Advantages:

- Adjustable contact time of the product with the connectors

- High yield

- Suitable for heat sensitive products

- Reduces the need for drying

- Energy-saving

- Ease of operation and maintenance.