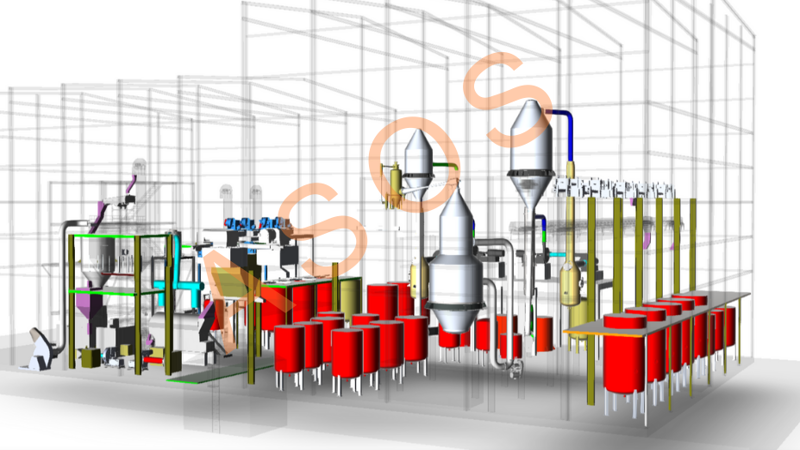

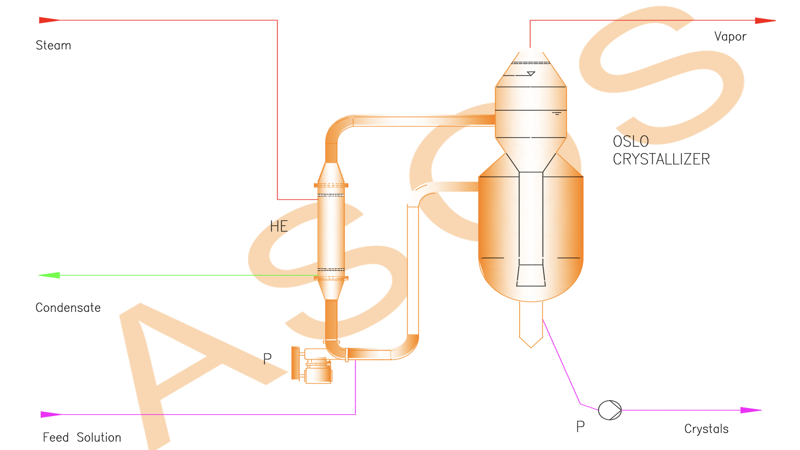

Oslo-Type Crystallizers have been developed in facilities with extensive design experience and are optimized for the production of large-sized crystals. In this type of crystallization, the excess supersaturation of the main solution is eliminated by coming into contact with large crystals. The majority of these crystals are kept in suspension, which enables the production of large crystals with a narrow size distribution.

The classification crystallization section forms the lower part of the crystallizer unit. In the upper part, there is a liquor-vapor separation area where the solvent (usually water) is evaporated. The slightly supersaturated liquor flows downward through a central tube and removes the excess supersaturation by coming into contact with the fluidized crystal bed.

The operating costs of Oslo-type crystallizers are lower compared to other types, especially when large crystals are needed. Since the crystals do not come into contact with agitators, the quantity of fine particles and consequently the energy requirement is lower. Oslo-type crystallizers can operate with long production cycles between washing periods.

Advantages:

- Operating costs are much lower compared to other types of crystallizers.

- Allows continuous operation with low maintenance requirements.

- Permits long production cycles between washing periods.

As a result, Oslo-type crystallizers are an economical and efficient choice for applications that require the production of large-sized crystals.