In the Chemical and Fertilizer Industry, Rotary Granulators are frequently preferred with the advantages they have in the granulation of fertilizers such as NPK/DAP/TSP/SSP and many chemical products.

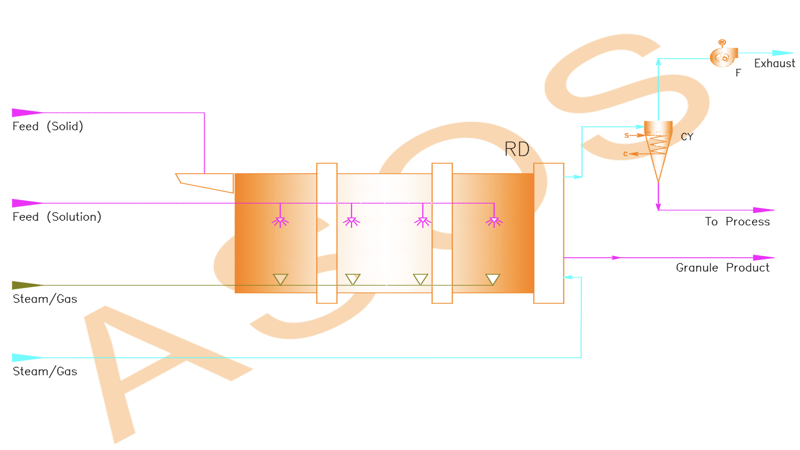

The general working principle of rotary granulators is based on the wet granulation process. A certain amount of liquid and/or gas and powdery substances are interacted in the granulator under a certain liquid/gas/solid phase condition with the aid of the rotational motion of the granulator.

In fertilizer production, steam, gaseous ammonia, phosphoric and sulfuric acid and other chemical additives are subjected to agglomeration process with the help of chemical reaction and heat in rotary granulators. Drying, cooling and coating processes are applied for suitable conditions at the exit of the granulator. Granules with unsuitable granule size are fed into the regranulation process.

Advantages:

- High granular product capacity

- Special design according to granule properties

- Suitable for mixing liquid, gas and solid materials

- Suitable for coarse grain sizes

- Robust and low maintenance